Controlled bolting

We achieve great results using controlled bolting methods. This includes hydraulic bolt torquing, hydraulic bolt tensioning, ultrasonic bolt monitoring, flange spreading and hydraulic nut splitting.

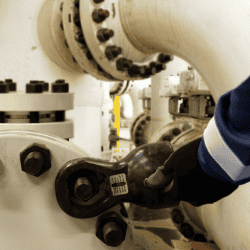

Hydraulic Bolt Torquing

This is the most widely used bolting method for controlled bolt tightening, due to its practicality and accessibility. Our hydraulic torque equipment is the safest and most advanced equipment available and the in-depth technical knowledge and expertise of our highly skilled technicians will ensure accurate bolt loading.

We also have a dedicated engineering department which can offer bespoke engineering solution for any challenging or problematic applications.

Hydraulic Bolt Tensioning

The fastest and most accurate method of controlled bolt tightening currently in use, hydraulic bolt tensioning enables a direct load to be applied evenly across all bolts and eliminates the factors introduced via bolt torquing operations.

Continuing investment in the latest tensioning technologies ensures we always have the right tool for standard and non-standard applications.

Ultrasonic Bolt Monitoring

When dealing with certain critical applications we may need to determine a more precise bolt load. We use our proven tightening techniques and highly accurate ultrasonic bolt monitoring equipment to achieve a “fully controlled tightening method”. Measuring the actual elongation means we can eliminate variables such as friction or load transfers factor, giving an accurate reading of bolt load, stress or % strain.

Flange Spreading

Our Mechanical and Hydraulic flange spreading system provides our technicians with a fast method of accessing gaskets in all types of flanged connections. This dramatically reduces down time, increases efficiency and ultimately decreases the cost of a gasket change out.

Hydraulic Nut Splitting

KLINGER Integrity Services technicians utilise specialist hydraulic equipment to ensure the fastest and most effective removal of corroded or seized nuts. We eliminate the need for time-consuming operations such as cutting, grinding or chiselling, and make sure that client deadlines and targets can still be achieved.