Graphite Packings

Graphite Packings are intended to offer high temperature capability, good chemical resistance and markedly reduced spindle wear. By selecting or combining the many versions of Graphite Packings available – we are able to offer a versatile range of Graphite Packings with varied handling and performance characteristics. These include high conformability, resistance to extrusion, chemical purity, temperature and oxidation resistance amongst others.

Overview of types Graphite Packings

K3222

High-performance pure graphite valve and pump packing suitable for plant wide applications with excellent chemical and temperature resistance. Manufactured from expanded graphite for outstanding sealing ability.

- Suitable for high pressure, high temperature applications.

- Offering excellent sealing and operational reliability for both Original Equipment Manufacturers and plant users alike

- Fire-Safe

K3222W

High performance graphite packing with Inconel wire reinforcement for use at high pressures

- Suitable for high pressure, high temperature applications.

- Offering excellent sealing and operational reliability for both Original Equipment Manufacturers and plant users alike

- Fire-Safe

K40

An exceptional packing combining carbon and Inconel® for high-temperature and high-pressure valve applications. K40 also has a graphite lubricant to reduce stem wear and increase material density.

- Ideal for sealing valve glands in high pressure and temperature

- Excellent chemical resistance

- Often used as anti-extrusion rings with K35 rings

K44

A high purity, graphite based packing for both valve and pump applications, with additional graphite lubricant to further improve sealing performance and dynamic performance.

- High performance

- Excellent chemical resistance

- Often used as anti-extrusion rings with K35 rings

K46

A carbon based packing with graphite and lubricant for both valve and pumps applications

- High performance multi-service packing for both valve and pump applications.

- Excellent chemical resistance

- Often used as anti-extrusion rings with K35 rings

K35 - Rings

sealing solution for high performance valve applications which require excellent pressure and temperature characteristics.

- The material has excellent thermal conductivity and thermal resistance.

- Can be used with braided header and footer rings for high pressure applications

- K35 die-formed rings are unaffected by fluctuations during application, such as thermal cycling.

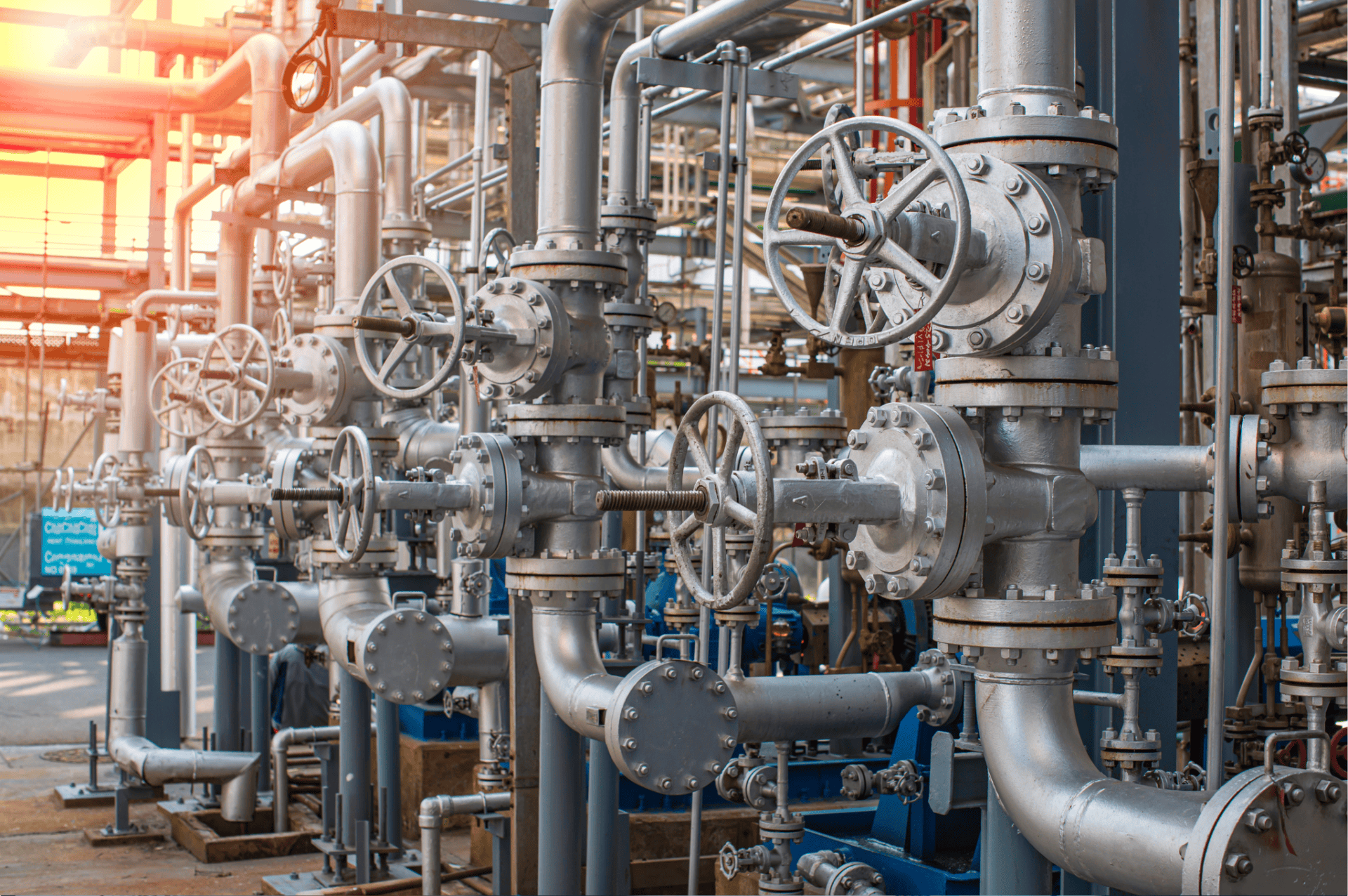

Related industries

Chemical

Sealing technology from KLINGER meets the high requirements of the chemical and petrochemical industry. We focus on ensuring plant and environmental safety by providing top-quality and durable products.

Oil & Gas

Our products provide the leading solutions both on and offshore within the oil & gas industry. We provide the first choice in terms of safety and reliability.