Synthetic Fibre Packings

An increasing variety of SYNTHETIC fibres are employed in the production of mechanical compression packings.

This is in response from industry for improvements in overall sealing capability. The demand by users for less leakage, downtime and wear combined with reasonable payback time remains the primary criteria for the use of SYNTHETIC packing. SYNTHETIC packings are increasingly finding favour because of the effective techniques employed by KLINGER in respect of the materials used, and in braiding and lubrication methods.

Overview of types Synthetic Fibre Packings

K10

A combination of Acrylic yarn and PTFE to produce a durable and economic sealing material

- Economic yet versatile synthetic packing,

- Suited to general service in valves and pumps

- WRc approved

- Also available with graphite instead of PTFE lubricant – K11

K11

An economical packing based on Acrylic-fibre yarn and graphite and an additional lubricant

- Economic yet versatile synthetic packing

- Suited to general service in valves and pumps

K25

High strength, aramid-fibre yarns with a KLINGERlock cross-braiding. With an additional PTFE lubricant.

- Suitable for abrasive and viscous media

- Ideal for sealing within extreme pumping applications - rotary or reciprocating.

K4303

A combination of selected glass fibre yarns and PTFE suitable for use in static sealing and valve applications

- A general valve and static seal packing

- Easy to cut, handle and install

K4310

A combination of selected glass fibre yarns and graphite, to produce a higher temperature packing for use in valves and static applications.

- Good thermal resistance, can be used up to 450°C

- A general valve and static seal packing

K4330

A universal packing, utilising Novoloid filament with PTFE lubricant. Especially suitable for rotary pumping applications where PTFE doesn’t posses sufficient strength.

- Can seal a wide range of media

- Suitable for pump applications

K4333

A strong, universal packing, using PTFE-lubricated polyimide filaments, with excellent strength. K4333 can be employed where shaft wear is a problem and will perform as a suitable alternative to aramid-fibre packings.

- A TopLine grade able to perform reliably in a wide range of services and equipment

- Suitable for low gland loads

- WRc approved

Related industries

Chemical

Sealing technology from KLINGER meets the high requirements of the chemical and petrochemical industry. We focus on ensuring plant and environmental safety by providing top-quality and durable products.

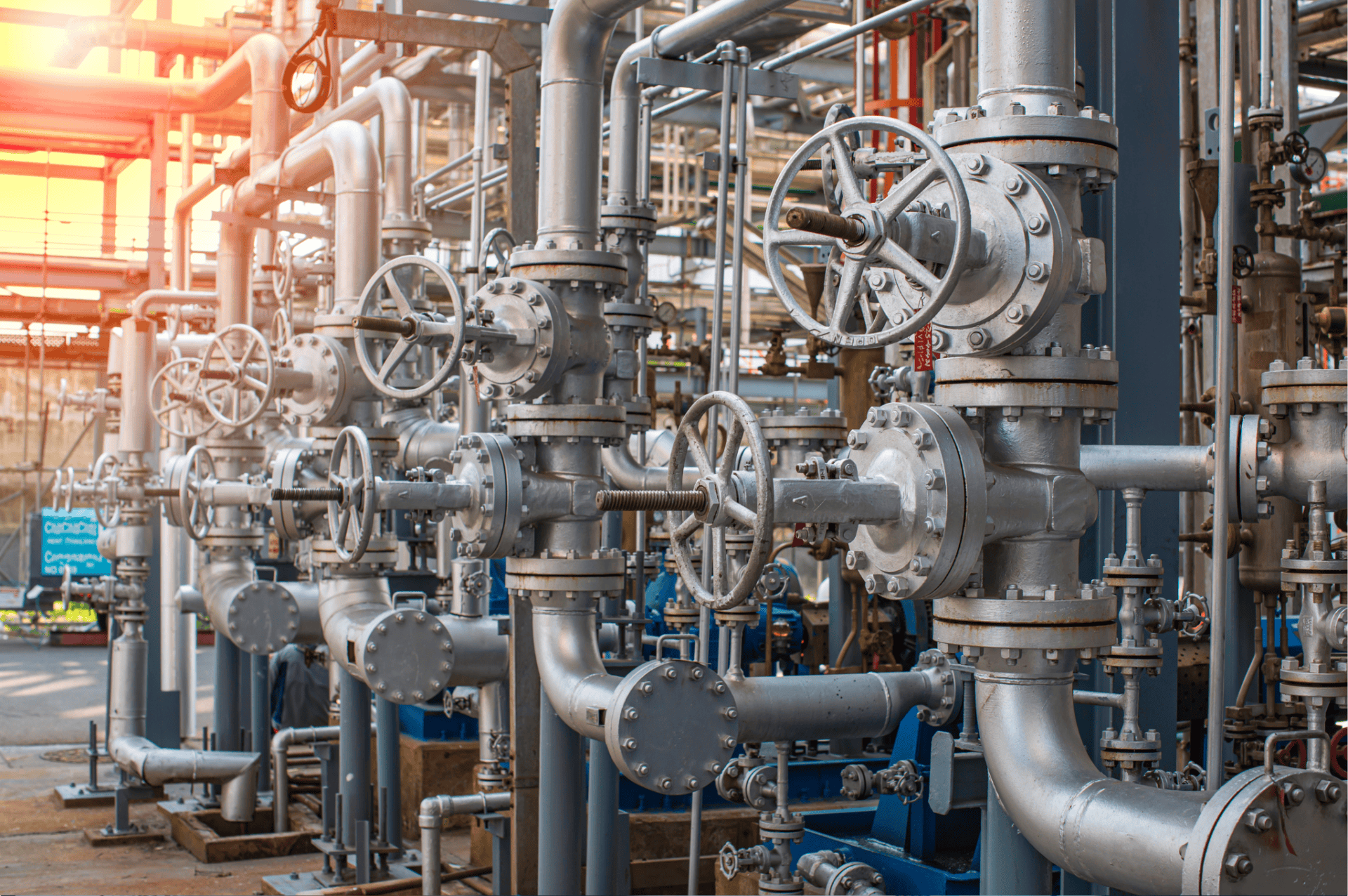

Oil & Gas

Our products provide the leading solutions both on and offshore within the oil & gas industry. We provide the first choice in terms of safety and reliability.

Pharmaceutical

Cleanliness and hygiene are non-negotiable factors within the pharmaceutical industry. Our products are in full compliance with the sector’s strict and demanding regulations and stand out thanks to their long service life.