Precision Engineering Facilities

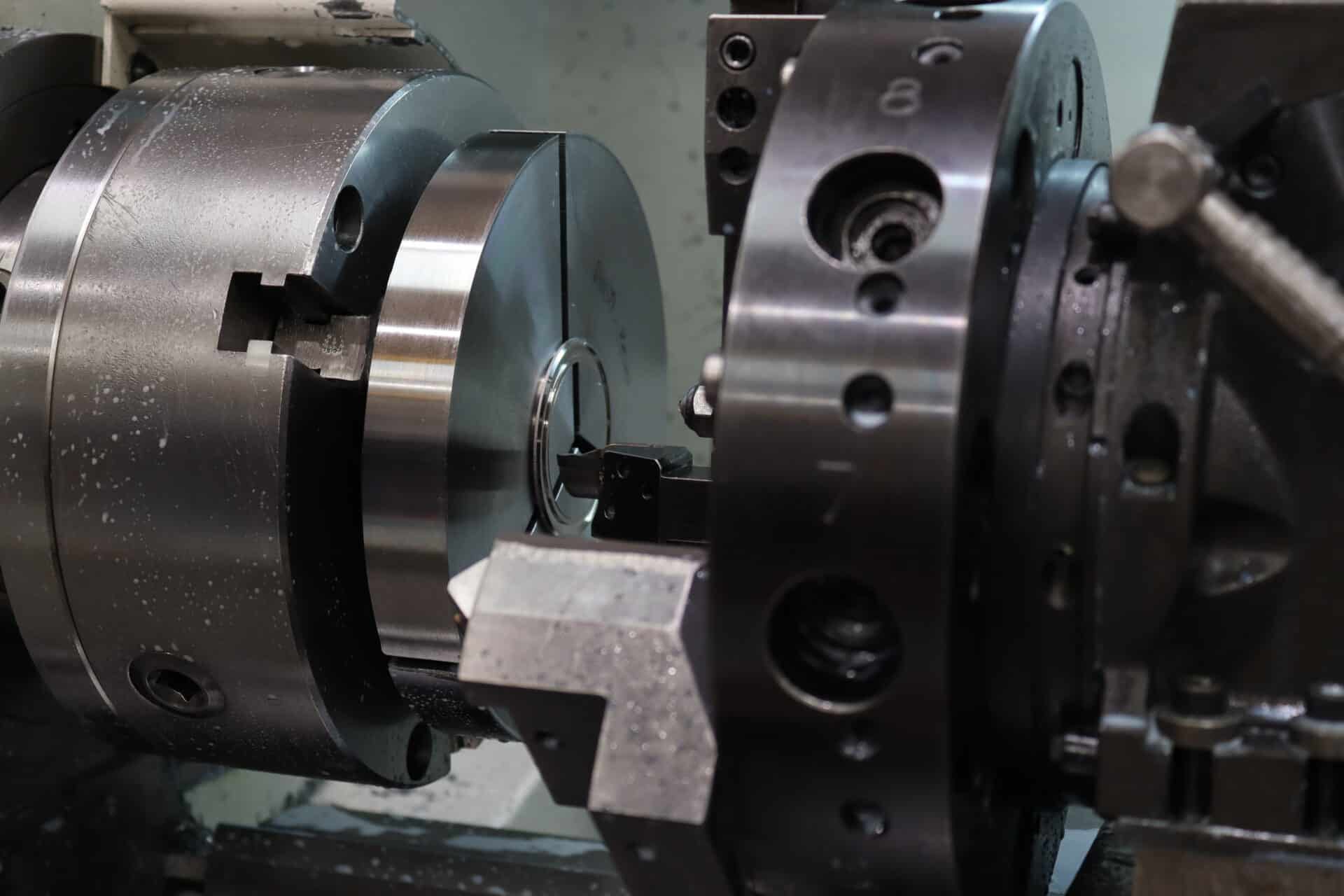

KLINGER UK’s precision production facility specialises in highly complex machined parts. Housing a range of specialised machinery, including CNC Milling and Turning, Surface and Cylindrical Grinding, as well as the latest WEDM equipment.

KLINGER UK’s state of the art facility dedicated to precision engineering comprises of highly complex machined parts. Our advanced precision production facility specializes in the manufacture of highly complex machined components, catering to the most demanding industries with unmatched accuracy and quality

State-of-the-Art Precision Engineering Facilities

Our facility houses a comprehensive range of specialized equipment, enabling us to deliver top-tier solutions:

- CNC Milling and Turning: Delivering precision engineering solutions for intricate geometries and high-volume production.

- Surface and Cylindrical Grinding: Ensuring perfect finishes and dimensional accuracy for critical components.

- Wire Electrical Discharge Machining (WEDM): Offering exceptional precision for cutting complex shapes from hard-to-machine materials.

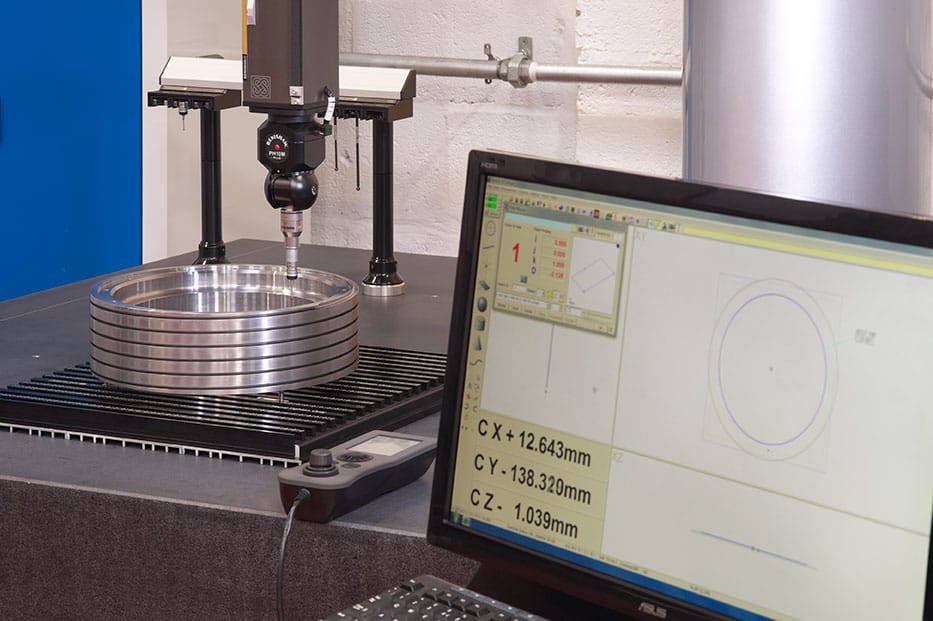

KLINGER UK’s facility dedicated to Precision Engineering is trusted by the offshore Oil and Gas industry for manufacturing exotic alloy Ring Type Joint (RTJ) gaskets. Our deep expertise in Precision Engineering allows us to create components capable of withstanding extreme pressures and temperatures, ensuring safety and reliability in challenging environments.

Products

- BOP wellhead rings

- Machined components from one-off bespoke products to multi-batch work

- Tubesheets

- Press tool design & manufacture

- Baffle plates

Capabilities

- Wire erosion

- Milling

- Grinding

- Turning

- High precision measurement using latest CMM equipment

Discover Precision Engineering Today

To find out more about our Precision Engineering facility, you can contact our team of expert technicians here.